J Morita Lubrina 2 Seamless Handpiece Auto-Maintenance System

JMO-24-K325ENGJ Morita Lubrina 2 Seamless Handpiece Auto-Maintenance System

Description

The fast and clean operation, plus compatibility with multiple brands of spray lubricant

Automatic purging and lubrication of a wide variety of equipment

New clean air-blow system

Reduced maintenance time and oil consumption

Up to 4 handpieces/attachments may be cleaned in the same cycle

Built-in chuck maintenance system for MORITA instruments

Compatible with 4-hole, 5-hole, and 6-pin connections

Unique dual lubrication system.

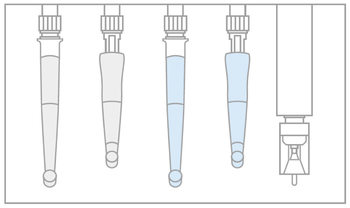

Lubrina 2 automatically performs maintenance (lubrication and cleaning) of handpieces and other equipment which are essential for daily practice. Because the lubrication amount and service time suitable for each handpiece are programmed into Lubrina 2, it can automatically perform maintenance of up to four handpieces in a short time. The clean air-blow system implements lubrication and cleaning of the inside of the handpiece thoroughly, and provides stable maintenance without variations by staff which can occur during manual lubrication. Lubrina 2 accepts multiple brands of spray lubricant.

- Cleans one turbine in approximately 20 seconds

- Oil usage amount is reduced to 1/4

- Faster maintenance with excellent cost savings

Handpiece and spray compatibility

Example: One turbine and contra angle by Morita and one turbine and contra angle by another manufacturer.

By replacing the coupling, Lubrina 2 facilitates the maintenance of Tri Auto ZX2 and Root ZX II contra angles, air driven handpieces (ISO 9168/Type 3 joint) as well as all other contra-angles and straight handpieces (ISO 3964/E-Type joint). Lubrina is compatible with 4-hole, 5-hole, and 6-pin connections. With its dual lubrication system, one or two different brands of spray may be used in the same cycle. Several brands of spray are compatible by using an optional spray holder adapter.

Clean Air-Blow System & Other Ease of Use Features

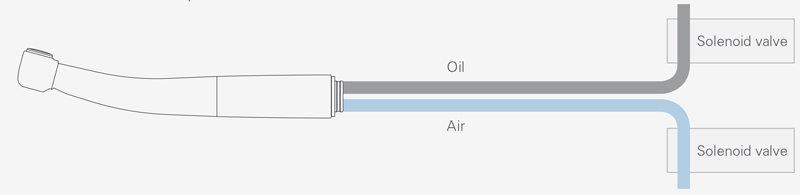

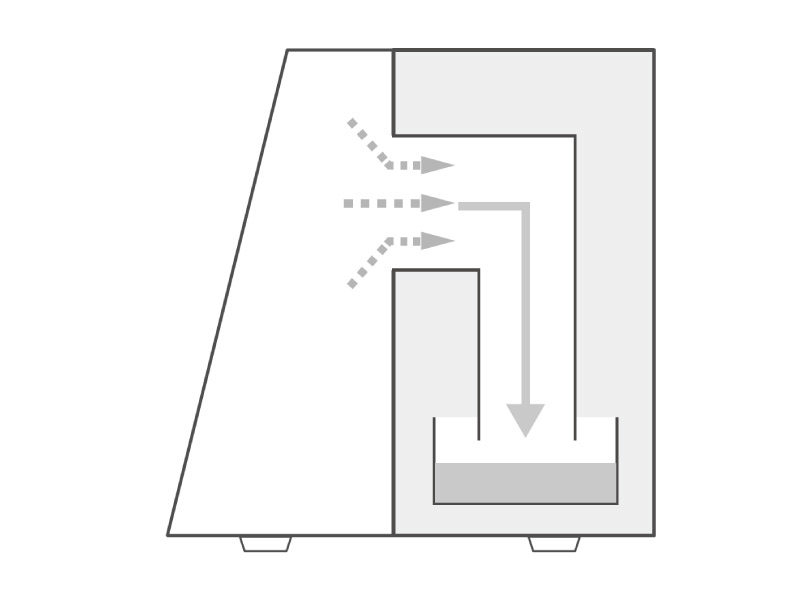

Double-conduit design achieves clean air

By employing the dual solenoid valves and clean air dedicated conduit, the system can supply clean air without a mix of oil. During the water removal process before lubrication, the system removes the water in the head which maximizes lubrication results. During idling after lubrication, the surplus oil can be effectively removed by clean air.

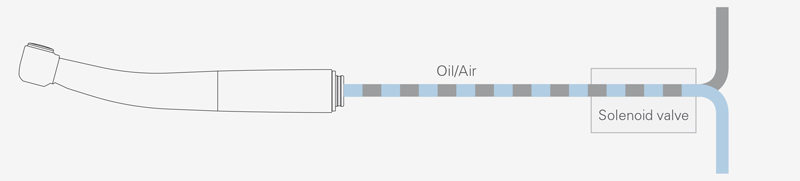

Comparision of Lubrina 2 with an conventional product

Lubrina 2 (Clean Air-Blow System)

Conventional product*

Additional benefits and ease of use features of Lubrina 2:

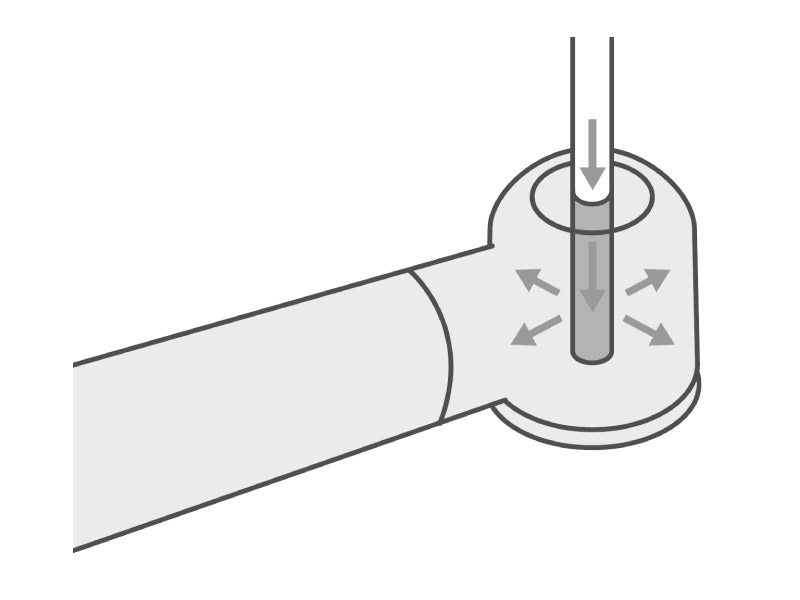

Easy chuck maintenance

For the turbine and 5x speed contra-angle handpiece, it is essential to lubricate and clean the chuck which holds the bar.

Water removal during autoclaving

If autoclave is performed while a large amount of water is left in the conduit of the handpiece, steam will not infiltrate and could cause a sterilization defect. To prevent this, clean air (without a mix of oil) is fed into the water feed, chip air conduit to remove the residual water, thereby reducing the possibility of a problem during autoclaving.

Surplus oil removal reduces idling time before practice

During handpiece rotation, clean air removes the surplus oil which causes blow-out, and thus reduces the idling time necessary before use.

Reduces scattering of oil mist

The built-in oil mist suction mechanism draws in the oil mist generated during maintenance, thereby preventing the mist from scattering to nearby surfaces and devices. In addition, since oil mist is collected into the oil gathering tray, maintenance of the equipment is also easy.

Reduced operating sound

Lubrina 2 of fers a noise reduction of 15dB during operation compared to the original model.

Easy maintenance

The control panel is flat and the front door can be removed for easy access and cleaning.

Oil spray can delivery system

The low viscosity oil mist penetrates into the inside of the handpiece head and delivers intense cleaning.

Packaging:

System includes: MORITA Lubricant Spray (2) (420ml ea), Oil Absorbent Tray Pad (1), Oil Absorbent Sheet (1), MORITA Spray Can Stands (2), Power Cord (1), Air Tube (1), Door Oil Absorbent Sheet (1), Front Door Sheet Stopper (1)